|

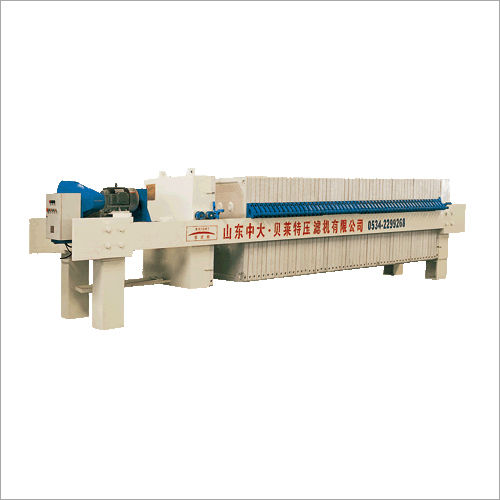

Manual Filter Press

Manual Filter Press Specification

- Product Type

- Manual Filter Press

- General Use

- Solid-Liquid Separation

- Material

- Cast Iron Frame, Polypropylene Plates

- Type

- Plate & Frame Filter Press

- Capacity

- Varies (customizable, typically from 200 to 2000 liters/hr)

- Weight (kg)

- Approx. 350-600 kg (depends on size/model)

- Computerized

- No

- Automatic

- No

- Ozone Generator

- Not Included

- UV Sterilizer

- Not Included

- Control System

- Manual Operation

- Filter Bag No.

- Depending on plate quantity (typically 10-25 plates)

- Filter Area

- 2-20 m (based on model)

- Flow Rate

- Up to 2000 liters/hr

- Voltage

- Not Applicable (Manual)

- Dimension (L*W*H)

- Approx. 1500 x 600 x 1100 mm (varies by model)

- Feature

- Corrosion Resistant, Easy Operation, Robust Construction

- Color

- Blue/Grey

- Discharge Type

- Open or Closed Discharge

- Maximum Working Pressure

- 5-7 Bar

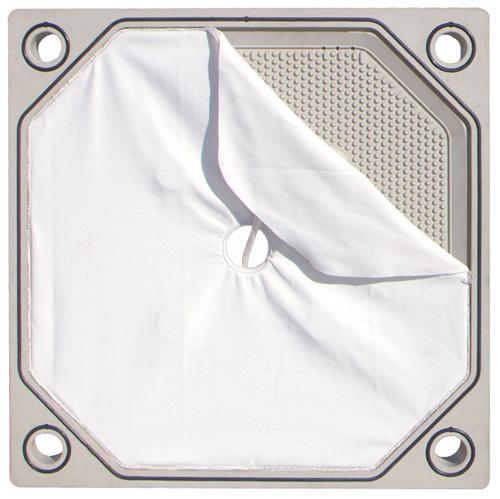

- Plate Size

- 470 x 470 mm (typical)

- Operating Temperature

- -10°C to 80°C

- Closing Mechanism

- Manual Screw Jack

- Gasket Type

- Non-gasketed / Center Feed

- End Plate Material

- MS Painted / SS Optional

- Application

- Chemical, Pharmaceutical, Food & Beverage, Effluent Treatment

- Number of Plates

- 10-25

- Cake Thickness

- 20-30 mm

Manual Filter Press Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Manual Filter Press

Established in the year 2002, we are the China based company engaged in the business of manufacturing Manual Filter Press. It is used by filling the slurry in each chamber which consists of a filter cloth attached to steel plate. This press is required for separating solid and filtrate from slurry. The solid layer of sludge cake forms on the filter cloth due to the pressure, which is then later removed easily. The resistance of filtration increases in Manual Filter Press with the thickness of filter cake.

Features:

- Excellent cake holding capacity

- Assures better filtrate quality

- Good dewatering and dry solid production ability

Versatile Solid-Liquid Separation

Engineered for versatility, this manual filter press is suitable for applications in the chemical, pharmaceutical, food, and effluent treatment industries. Its robust frame and corrosion-resistant plates make it reliable for various harsh and demanding environments. The system efficiently separates solids from liquids, supporting processes that require clarity and purity in end products.

User-Friendly, Manual Operation

This filter press employs a manual screw jack closing mechanism, eliminating the need for electrical connections or computerized controls. All operations, from plate tightening to cake discharge, are performed by hand, making it ideal for locations with limited infrastructure or where simple, dependable machinery is needed.

Customizable Capacity and Discharge Options

Capacities are flexible, ranging from 200 to 2000 liters per hour, with filter area and number of plates customizable to suit specific process needs. Users can choose between open and closed discharge systems, adapting the press to different operational preferences or regulatory requirements while ensuring effective filtration outcomes.

FAQs of Manual Filter Press:

Q: How is the manual filter press operated and what is the closing mechanism?

A: The manual filter press is operated using a screw jack closing mechanism, allowing the operator to manually tighten the plates and initiate filtration. No power or computerized control is required, making it straightforward and easy to use.Q: What applications is this filter press best suited for?

A: This filter press is ideal for solid-liquid separation in chemical, pharmaceutical, food and beverage, and effluent treatment processes. Its corrosion resistance and robust construction support demanding industrial environments.Q: When should the plates be cleaned or replaced during routine operation?

A: Plates should be cleaned after each filtration cycle to prevent clogging and maintain efficiency. Replacement is necessary if plates show signs of wear, persistent fouling, or physical damage that affects sealing and performance.Q: Where can this filter press be installed, considering its operational requirements?

A: This press can be installed in locations without electrical infrastructure or computerized systems, such as small-scale production sites or remote facilities, provided there is enough space to accommodate its dimensions and manual operation.Q: What is the typical filtration process using this filter press?

A: The process involves assembling and tightening the plates using the manual screw jack, feeding the slurry through the center feed, and filtering out solids onto the plates. After the cycle, plates are released, and the separated cake is removed for disposal or further use.Q: How does the non-gasketed, center feed design benefit users?

A: A non-gasketed, center feed design simplifies maintenance and cleaning. It also reduces downtime due to gasket failure and lowers overall operating costs while providing reliable, efficient filtration.

Price 20000 INR/ Set

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Press Category

Programmed Controlled Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

General Use : Industrial SolidLiquid Separation

Product Type : Programmed Controlled Filter Press

Motor : Other, 3 HP

Material : Other, HighGrade Steel Frame, Polypropylene Plates

Mechanical Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

General Use : Solidliquid separation in industrial applications

Product Type : Mechanical Filter Press

Motor : Other, 3 HP / 5 HP Electric Motor (optional for mechanical drive)

Material : Other, Mild Steel / Cast Iron

Horizontal Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

General Use : Solidliquid separation in industrial filtration processes

Product Type : Horizontal Filter Press

Motor : Other, 0.75 kW to 7.5 kW

Material : Other, SS304 / SS316 Stainless Steel

Waste Water Treatment Filter Press

Price 3000 USD ($) / Set

Minimum Order Quantity : 1 Set

General Use : Waster water treatment

Product Type : Automatic

Motor : AC Motor

Material : Carbon Steel

|

ZHONGDA BRIGHT FILTER PRESS CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

: +8615863766971

: +8615863766971