|

Automatic Membrane Filter Press

Automatic Membrane Filter Press Specification

- Product Type

- Automatic Membrane Filter Press

- General Use

- Industrial Solid-Liquid Separation

- Material

- Mild Steel / Stainless Steel

- Type

- Membrane Filter Press

- Capacity

- Customizable as per requirement

- Weight (kg)

- Varies with model, typically 2000-8000 kg

- Computerized

- Yes

- Automatic

- Yes

- Ozone Generator

- No

- UV Sterilizer

- No

- Control System

- PLC Control Panel

- Filter Bag No.

- Multiple Plates (24-60 as per model)

- Filter Area

- 60-600 m (as per model)

- Flow Rate

- 500-4000 L/H

- Voltage

- 380V/415V 3 Phase

- Motor

- 3-7.5 kW

- Dimension (L*W*H)

- Customizable, representative: 6000 x 1800 x 1600 mm

- Feature

- Automatic Plate Shifting, Cloth Washing System, High Dewatering Efficiency

- Color

- Industrial Blue/White

- Safety Features

- Pressure Relief Valve, Emergency Stop Switch, Safety Interlocks

- Noise Level

- <70 dB(A)

- Frame Structure

- Heavy Duty Welded Construction

- Plate Size

- 470x470 mm / 630x630 mm / 800x800 mm / 1000x1000 mm / Custom

- Feeding Pressure

- 0.6-1.6 MPa

- Slurry Inlet Type

- Central/Corner (Customizable)

- Filtration Cycle Time

- 30-90 minutes depending on feed

- Operation Mode

- Fully Automated

- Hydraulic System

- Electric-Hydraulic

- Discharge Method

- Automatic Cake Discharge

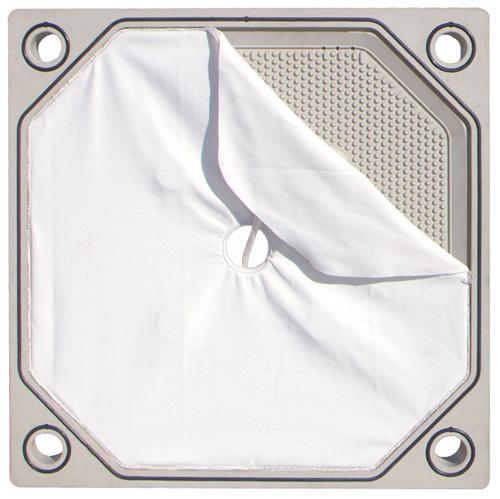

- Membrane Type

- PP Membrane/ EPDM

- Ambient Temperature

- 5°C-45°C

- Application

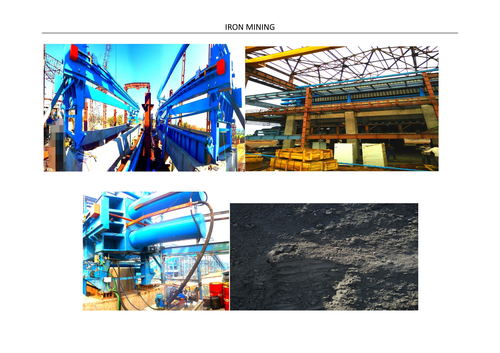

- Effluent Treatment, Chemical Industry, Food & Pharmaceutical, Mining, Metallurgy

- Plate Material

- PP (Polypropylene), Cast Iron (Optional)

- Max Cake Thickness

- 30-50 mm

Automatic Membrane Filter Press Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

About Automatic Membrane Filter Press

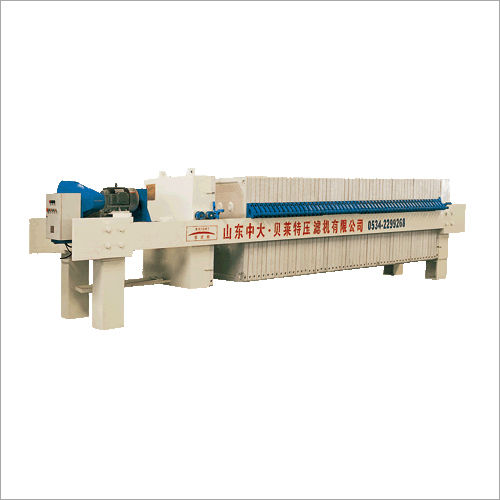

We have received great admiration from our clients for manufacturing and supplying Automatic Membrane Filter Press. It consists of a diaphragm compressor, filter plate, frame filter, and shifters to move plates and allow rapid discharge of accumulated cakes. The pumped slurry passes through each frame of specific mesh sizes and forms a layer of solids on each of them giving a pure filtrate which moves out from the outlet. Offered Automatic Membrane Filter Press is operated by electronic control panel that allows automatic pushing & pulling of filter plates at the maintained pressure.

Features:

- Automatic cleaning of filter cloth

- Smooth and low noise working

- Ideal to be used for viscous slurries

Precision Engineering for Demanding Applications

This automatic membrane filter press is engineered for intensive industrial processes, combining a sturdy mild steel or stainless steel frame with high-quality polypropylene plates for optimum durability and performance. The hydraulic system is electrically operated, enabling precise pressure control and fully automated sequence operationsideal for facilities requiring consistent reliability like mining, effluent treatment, and chemical production.

Customizable Plates and Filtration Cycles

With plate sizes ranging from 470x470 mm to 1000x1000 mm (and custom options), the filter press can be configured to fit varying volume and filtration needs. Cycle times, cake thickness, and configuration of slurry inlet (central/corner feed) are easily tailored to specific process requirements, ensuring adaptability across diverse solid-liquid separation scenarios.

Advanced Safety and Ease of Operation

User safety is a focal point, highlighted by features like pressure relief valves, emergency stop switches, and robotic safety interlocks. The PLC control panel provides intuitive operation and monitoring, simplifying integration into modern automated production lines. Automatic plate shifting and cloth washing systems further reduce operator intervention and increase processing efficiency.

FAQs of Automatic Membrane Filter Press:

Q: How does the automatic membrane filter press operate in a fully automated environment?

A: The automatic membrane filter press operates through an electric-hydraulic system managed by a PLC control panel. Once initiated, the system automates plate shifting, slurry feeding, membrane squeezing, cake discharge, and cloth washing, reducing manual labor and maximizing process consistency.Q: What materials are used in the construction of the filter plates and membranes?

A: Filter plates are primarily made of high-quality polypropylene (PP), though cast iron options are available upon request. Membranes can be fabricated from either PP or EPDM, chosen based on compatibility with the process fluid and required mechanical properties.Q: When should I use an automatic membrane filter press instead of a standard filter press?

A: An automatic membrane filter press is recommended when high dewatering efficiency, rapid cycle times, and minimal manual operation are neededsuch as in continuous industrial applications, or when handling large volumes or challenging slurries in sectors like mining, pharmaceuticals, and wastewater management.Q: Where is this filter press typically installed and used?

A: This filter press is commonly installed in industrial facilities, effluent treatment plants, mining operations, chemical manufacturing sites, and food or pharmaceutical production linesanywhere reliable and efficient solid-liquid separation is required.Q: What process steps are involved in the filtration cycle?

A: A typical cycle involves feeding the slurry into the press, primary filtration under controlled pressure, membrane squeezing (for further dewatering), automatic cake discharge, and automated cloth washing. The filtration cycle time varies between 30 and 90 minutes, depending on slurry properties and model configuration.Q: What are the key benefits of using this membrane filter press?

A: Major benefits include high dewatering efficiency, consistent cake dryness, reduced process downtime due to automation, compatibility with various slurry types, robust safety features, customizable capacity, and quiet operation (less than 70 dB[A]).Q: Can the filter press be customized to fit unique process requirements?

A: Yes, multiple aspects such as plate size, number of filter plates, feed pressure, cycle time, filter area, and cake thickness can be customized. Options for material construction and automated features are also available to match specific operational needs.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Membrane Filter Press Category

High pressure Membrane Filter Press

Minimum Order Quantity : 1 Set

Ozone Generator : Other, Optional

Filter Bag No. : Up to 100 (depends on plate size)

UV Sterilizer : Other, Optional

General Use : Industrial solidliquid separation

Membrane Filter Press

Minimum Order Quantity : 1 Set

Ozone Generator : Other, Available as option

Filter Bag No. : Varies by Model (30 100)

UV Sterilizer : Other, Available as option

General Use : Solidliquid separation, Sludge dewatering

Ultra High Pressure Membrane Filter Press

Minimum Order Quantity : 1 Set

Ozone Generator : Other, Optional

Filter Bag No. : Customized (Multiple Plates/Chambers as per requirement)

UV Sterilizer : Other, Optional

General Use : Solidliquid Separation in Industrial Filtration

|

ZHONGDA BRIGHT FILTER PRESS CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

: +8615863766971

: +8615863766971