|

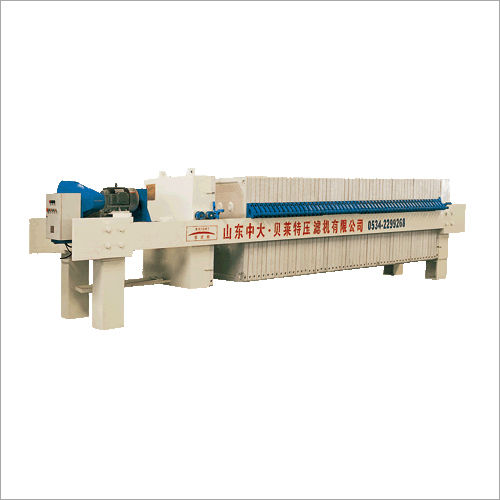

Programmed Controlled Filter Press

Programmed Controlled Filter Press Specification

- Product Type

- Programmed Controlled Filter Press

- General Use

- Industrial Solid-Liquid Separation

- Material

- High-Grade Steel Frame, Polypropylene Plates

- Type

- Fully Automatic Filter Press

- Capacity

- Up to 1000 L/hour (varies by model)

- Weight (kg)

- Approx. 1200 kg (varies by size/model)

- Computerized

- Yes

- Automatic

- Yes

- Ozone Generator

- Optional

- UV Sterilizer

- Optional

- Control System

- PLC Based Control Panel

- Filter Bag No.

- Multiple (as per configuration)

- Filter Area

- Up to 60 m (as per model)

- Flow Rate

- Up to 1000 L/hour

- Voltage

- 440 V, 3 Phase, 50 Hz

- Motor

- 3 HP

- Dimension (L*W*H)

- 4100 mm x 1300 mm x 1400 mm (varies by model)

- Feature

- Automatic Plate Shifting, Low Maintenance, Safety Interlocks

- Color

- Industrial Blue/White

- Noise Level

- <70 dB

- Cake Thickness

- 25 mm to 45 mm

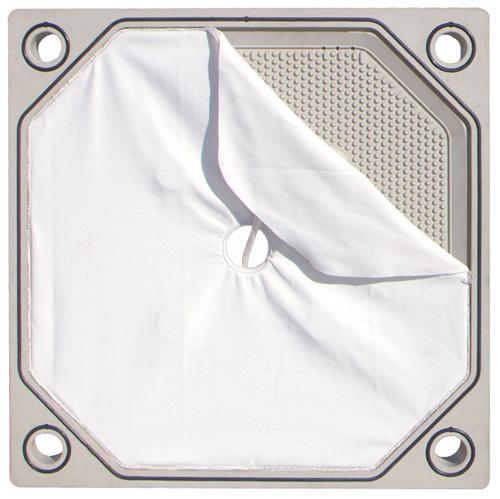

- Filter Cloth Material

- Polypropylene/Nylon

- Frame Coating

- Epoxy Powder Coated

- Filtration Pressure

- Up to 15 bar

- Operational Temperature Range

- Up to 80°C

- Discharge Type

- Automatic Cake Discharge

- Safety Features

- Overload Protection, Emergency Stop, Safety Guards

- Plate Size

- 500 mm x 500 mm to 1500 mm x 1500 mm

- Hydraulic System

- Electro-Hydraulic Power Pack

- Application Industries

- Chemical, Pharmaceutical, Food & Beverage, Mining, Effluent Treatment

Programmed Controlled Filter Press Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Programmed Controlled Filter Press

Backed by our diligent professionals, we are becoming as one of the promising manufacturers and exporters of Programmed Controlled Filter Press. This machine is operated with the help of PLC based control panel which automatically performs plate shifting, filter plate pressing, and open & close of door. It works on hydraulic system to assure smooth operation and durability. Offered Programmed Controlled Filter Press is known to have the ability to produce large amount of cake from single filter at one time.

Features:

- Equipped with a dust cover for hydraulic rod

- Can also be provided with cloth vibrating and washing system

- Pressure is maintained with the help of electrical contract pressure gauge

Advanced Filtration Technology

This filter press utilizes a PLC-based computerized control system for seamless, unattended operation. With automatic plate shifting and cake discharge, it delivers efficient solid-liquid separation and reduces operator intervention. The system supports various industries, offering flexibility in plate sizes and filtration capacities up to 1000 L/hour, depending on the model.

Robust and Safe Construction

Manufactured with a high-grade steel frame and epoxy powder coating, the filter press offers excellent resistance to corrosion and mechanical stress. Its multiple integrated safety features, including overload protection, emergency stop, and customized safety guards, help maintain the highest standards of workplace safety in demanding industrial environments.

Easy Maintenance and Custom Features

Low maintenance requirements, combined with user-friendly design for quick filter cloth replacement, minimize downtime. Optional enhancements like ozone generator or UV sterilizer are available to fulfill specialized process needs, while the systems modular design ensures compatibility with varied filtration requirements.

FAQs of Programmed Controlled Filter Press:

Q: How does the programmed controlled filter press operate during solid-liquid separation?

A: The filter press uses a PLC-based electro-hydraulic system to automatically create the necessary pressure for filtration (up to 15 bar). Plates are shifted automatically, and the process concludes with the discharge of compact filter cakes. Operators are able to control cycles and monitor status through a computerized control panel, ensuring consistent performance and minimal manual intervention.Q: What are the main benefits of using this fully automatic filter press?

A: Key benefits include high efficiency in solid-liquid separation, automated operation for reduced labor, low noise levels (<70 dB), and robust safety measures such as overload protection and emergency stops. The systems design supports low maintenance, easy filter cloth changes, and adaptable configuration for various industrial applications.Q: When should filter cloths and plates be replaced or maintained?

A: Filter cloths and plates should be inspected regularlyideally after each filtration cycle or batch. Replace cloths if significant wear, clogging, or damage is detected. Plates require replacement if cracked or deformed. Routine maintenance following manufacturer guidelines ensures optimal filtration quality and prolongs equipment life.Q: Where can this filter press be effectively implemented?

A: The system is suitable for industrial solid-liquid separation in sectors such as chemical production, pharmaceuticals, food and beverage processing, mining operations, and effluent treatment plants. Its adaptable plate sizes and filtration capacities accommodate a wide range of processing requirements.Q: What process parameters can be controlled with the PLC-based panel?

A: The PLC-based control panel allows users to adjust filtration time, pressure settings, plate shifting intervals, cake discharge timing, and monitor safety parameters. This automation improves process accuracy and repeatability, tailoring the operation to specific application needs.Q: How is operator safety ensured during filter press operation?

A: Operator safety is addressed through features like emergency stop buttons, overload protection systems, and safety guards around moving components. The filter press also features interlock systems that prevent operation if unsafe conditions are detected, minimizing the risk of accidents.

Price 20000 INR/ Set

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10000 Sets Per Year

- Delivery Time

- 1-2 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Press Category

Manual Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

Computerized : No

General Use : SolidLiquid Separation

Filter Area : 220 m (based on model)

Automatic : No

Mechanical Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

Computerized : No

General Use : Solidliquid separation in industrial applications

Filter Area : 5 40 m

Automatic : No

Horizontal Filter Press

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

Computerized : Other, Optional

General Use : Solidliquid separation in industrial filtration processes

Filter Area : 5 to 60 m

Automatic : Yes

Waste Water Treatment Filter Press

Price 3000 USD ($) / Set

Minimum Order Quantity : 1 Set

Computerized : Yes

General Use : Waster water treatment

Filter Area : 10800 m2 Square Meter (m2)

Automatic : Yes

|

ZHONGDA BRIGHT FILTER PRESS CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

: +8615863766971

: +8615863766971